- In design and prototyping, virtual reality enables users to explore multiple facets of a product before committing to any form of physical production.

- Virtual reality provides valuable, advanced information about ergonomic requirements for workers manufacturing specific parts and products.

- It is a sophisticated, real time training tool for production lines, simulating a broad range of environments and processes.

- Virtual reality has the power to accelerate the whole manufacturing process, enabling products to be launched much more rapidly.

Why is VR adoption crucial for manufacturing?

In a technologically advancing, highly-interconnected world, divisions between the digital and physical are blurring. Manufacturers can no longer afford to ignore the impact that digital technology is having on the marketplace as well as their ability to compete effectively. Like other industries, manufacturing must continue to look for new business models to help boost productivity and profitability. These include adapting processes, but also original ways of equipping employees with the skills they need to meet changing demands in production.- For research, design and review purposes, VR improves capabilities and accelerates time-to-market. It enables manufacturers to pinpoint and address potential problem areas in design while keeping costs down and keeping to schedule.

- It also provides a highly collaborative environment, offering improved communication for researchers, designers and developers.

- Optimising products quickly, accurately and efficiently is critical for manufacturers looking to maintain and improve their margins.

- Optimisation also extends to learning. Immersive VR can reduce the time it takes for operators to reach advanced proficiency levels, improve skills and maximise team training.

How is VR transforming the manufacturing process?

Traditionally, in the manufacturing process, research and design will culminate in the development of physical prototypes for subsequent testing and modification. This course of action can be both time-consuming and costly, with developers only being able to identify and mitigate weaknesses and faults once they have created a physical prototype. Virtual reality enables researchers and designers to accurately simulate physical conditions much earlier in the process. They can refine and modify prototype designs before committing resources to production. For the modification and refinement of existing products, VR offers valuable opportunities for testing and predictive analysis. This immersive technology is also transforming how manufacturing production lines prepare for products, including the management of risk and safety. For manufacturers, product lifecycle management (PLM) is vital to productivity and profitability. Virtual reality is helping to make this process faster and more cost-effective, in turn granting manufacturers improved agility to compete effectively. Figures from PwC research suggest that the use of virtual reality, and augmented reality, in product and service development could deliver a huge increase in GDP of over €320 billion in the next decade. This will come from accelerated time-to-market and rapid prototyping alongside improved efficiency, accuracy and productivity.What are the benefits of virtual reality in manufacturing?

The key benefits of immersive virtual reality in manufacturing are in product development and refinement and in production processes, including training. Optimised Design process & Enhanced PLM: Firstly, immersive technology can make the design process more efficient. The challenge for manufacturers is to design better products while also saving time and money doing so. Using VR, designers can test and optimise many different configurations at a much earlier stage in the process. This results in less need for successive prototypes when trying to perfect a design in preparation for production. It enhances product lifecycle management (PLM) significantly. Training: Secondly, VR can have a hugely positive impact on training and preparing the workforce for new product lines and new processes. Employees can train in real time while minimising risk and maximising the impact of repetitive and autonomous learning. Research shows that workers learn around 70 per cent of skills and knowledge through experiential learning. Virtual reality provides this learning but in a safe, risk-free, immersive environment. We have already mentioned how it can accelerate design, research and prototyping processes, and this drives the speed at which manufacturers can market products for sale.What are the applications of VR in manufacturing?

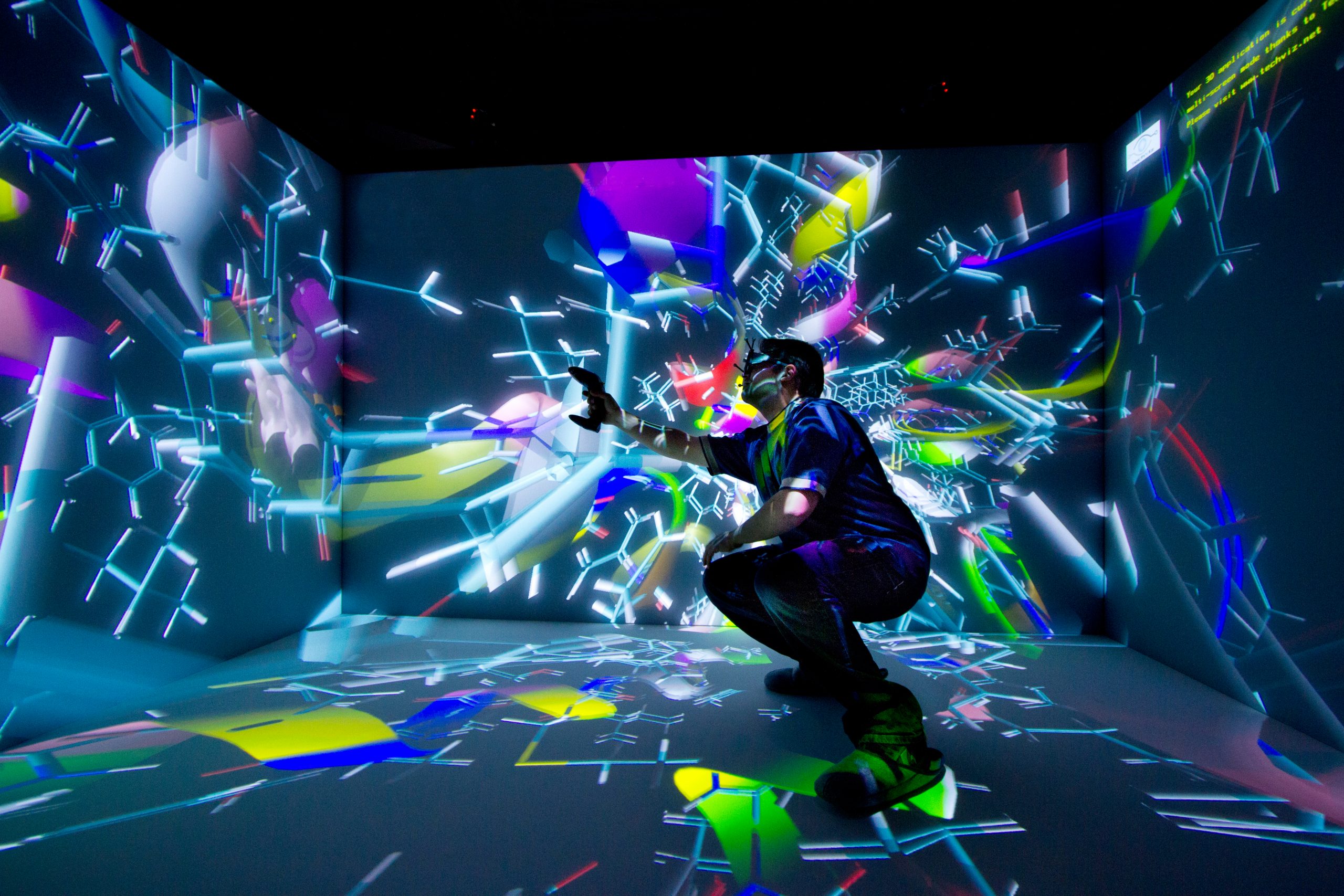

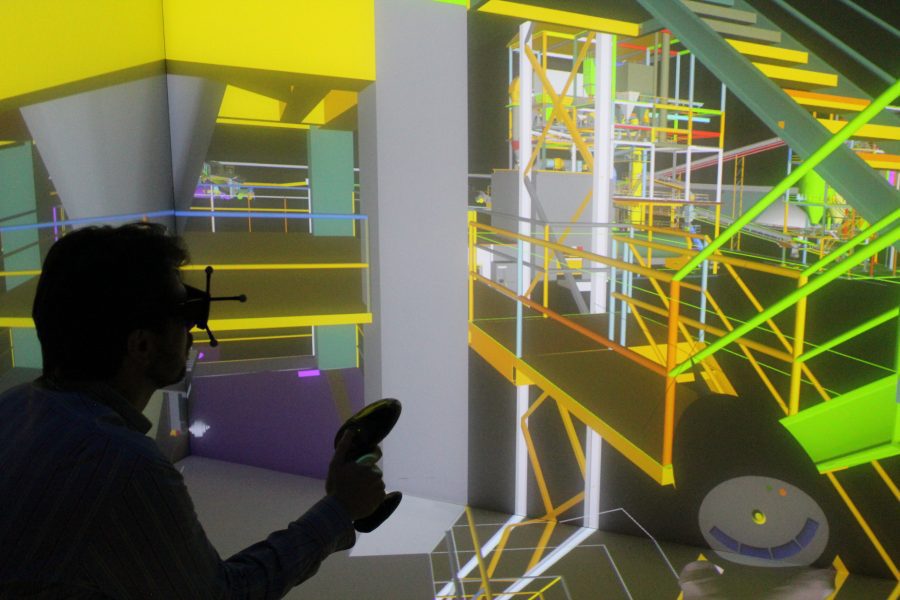

Because virtual reality is so versatile, it has potential applications in many types of manufacturing. We can best illustrate this versatility with specific examples. Hutchinson is a leading supplier in the automotive industry. It is now using two immersive VR rooms in its Innovation and Research Centre. Each of these is a four-sided CAVE (Cave Automatic Virtual Environment), which enables operators to enter a virtual 3D space, work in a virtual environment and interact with and manipulate their data in 3D. The VR CAVE offers advanced simulation capabilities to designers and engineers, enabling them to take a realistic, collaborative working approach in a simulated environment. The University of Leeds currently has the largest VR CAVE-based pedestrian simulation environment in the world. It is designed to support safe, experimental research in a repeatable fashion – and with a variety of variables – for elements including Automated Vehicle (AV) design. Professor Richard Romano, the university’s chair in driving simulation, said that the primary reason for building a HIKER was to investigate how humans interact with existing traditional vehicles before comparing their behaviour in the presence of automated ones. The data collected can be valuable at the design stage for manufacturers of cars and other road vehicles.

The University of Leeds currently has the largest VR CAVE-based pedestrian simulation environment in the world. It is designed to support safe, experimental research in a repeatable fashion – and with a variety of variables – for elements including Automated Vehicle (AV) design. Professor Richard Romano, the university’s chair in driving simulation, said that the primary reason for building a HIKER was to investigate how humans interact with existing traditional vehicles before comparing their behaviour in the presence of automated ones. The data collected can be valuable at the design stage for manufacturers of cars and other road vehicles.