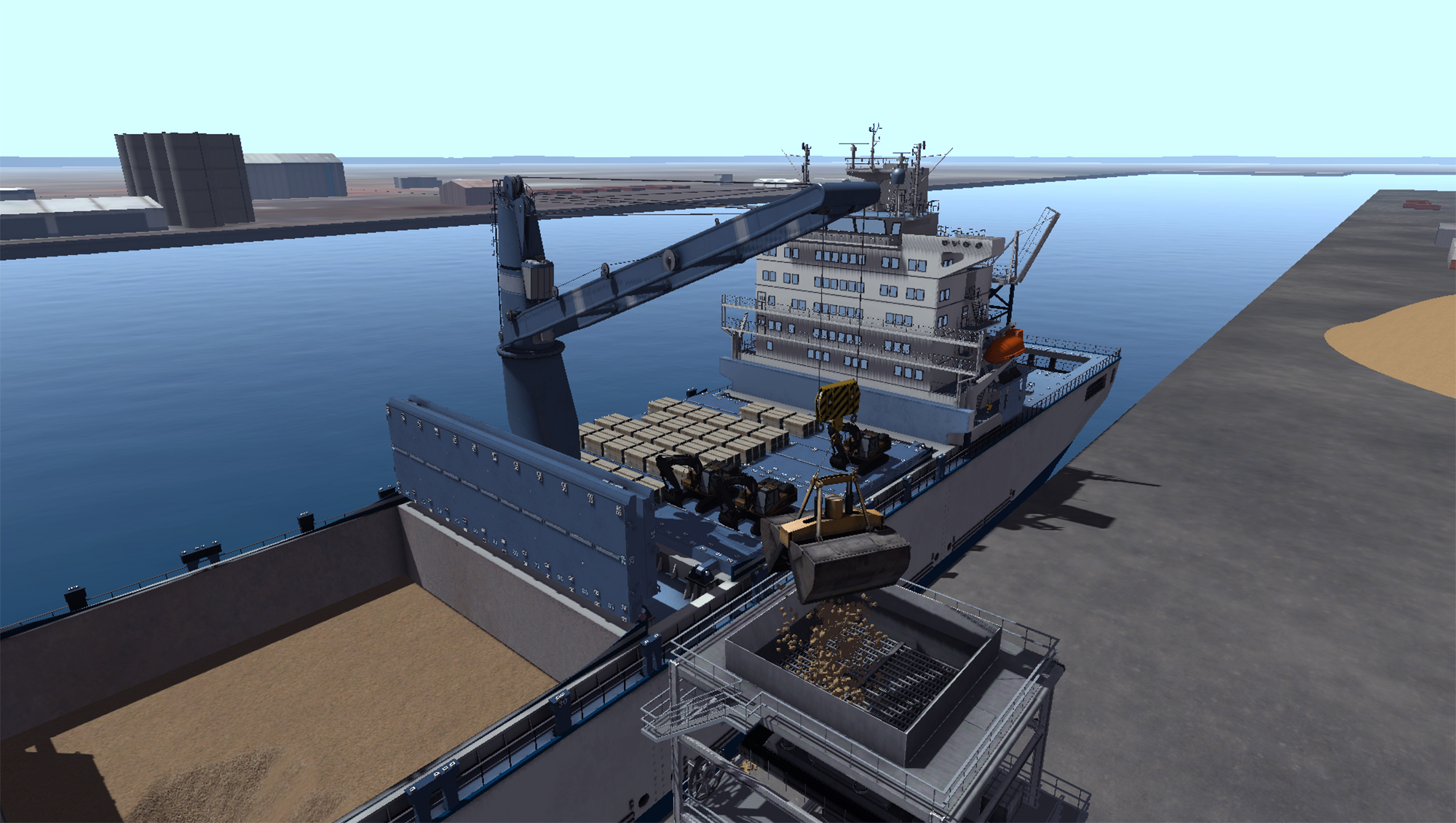

Simulation-based training can offer more to ports besides quayside crane operator training, with a range of true-to-life training packages for yard equipment. As automation increases in terminals, boosting quayside efficiency and streamlining ship-to-shore crane operations, there is a risk that bottlenecks will occur yard side.

The operation and performance of the yard side equipment can therefore impact on overall competitiveness and productivity in the port terminals.

An effective approach is to ensure that the skills and capabilities of port terminal operators align with a port's objectives.

With that in mind, ship to shore simulation-based training solutions for yard equipment offer fast, effective training.

ST Engineering Antycip and our partner CM Lab offer a range of simulators to help train heavy equipment operators and provides the leading operator training solutions for the maritime and port industries.

Read on to find out more about the benefits of using yard-side crane training simulators in the training of port terminal operators.

What are the benefits of simulation based yard equipment training solutions in port terminals?

Simulation-based training solutions for yard equipment in ports provide accelerated development opportunities, skills enhancement through adaptive learning, and potential cost savings.

Port equipment training simulators are tools that can increase safety and productivity, properly preparing yard side operators for handling real equipment.

Simulation training is risk-free, for instructors, operators and the equipment they train on.

These training solutions incorporate Smart Training Technology™ to drive transferable operator skills.

They offer operators progressive, competency-based training, providing them with an opportunity to develop skills according to their needs.

The system continually monitors performance, guiding users towards their goals.

Overall benefits of simulation-based training include:

- Rapid, effective training, with paths to operator readiness 25 to 55 per cent faster

- Objective assessment of trainees based on specific requirements

- More confident trainees

- Increased safety awareness, with simulation providing emergency response training and reconstructing accidents

- Productive operators from day one of using real equipment

- Experienced operators having easy access to training to refresh or enhance their skills

Types of Yard Equipment Training Simulators

Yard equipment training simulators cover the essential equipment that ports rely on to perform container handling both efficiently and safely.

1. Internal Transfer Vehicle

Using this simulator, trainees can learn how to operate an internal transfer vehicle (ITV) in a safe, highly-realistic, simulated work environment. They learn how to drive and manoeuvre an ITV safely, handle a trailer, while interacting with other port equipment and machinery.

It is a competency-based training package, designed to give trainees a grounding in the basics of driving and port procedures.

It takes the user through skill-specific training scenarios, including:

- Familiarisation with vehicle controls

- Trailer handling

- Picking and dropping containers

- Driving in reverse

- Turning

- Parking

- Manoeuvring within confined spaces

- Operations using a fifth wheel

Beyond an elementary understanding of controls, the Internal Transfer Vehicle simulator provides the user with a realistic, true-to-life experience, based on how real equipment operates.

2. Forklift

The forklift simulator gives trainees the skills they require to operate this equipment safely and effectively.

Simulation training exercises follow industry best practice so that trainees learn fundamental forklift handling skills, including:

- Driving and steering around objects

- Manoeuvring in confined spaces

- Fork spacing and positioning

- Load handling, including fragile and sensitive loads

- Loading and unloading in challenging conditions

- Avoiding collisions.

The training simulator is based on real life machinery and movements, with various programmable features including:

- Different load limits and vehicle responses

- Machine faults

- Pedestrian traffic

3. Rubber-tyred Gantry Crane

This simulator provides a safe, but rigorous, competency training package from which trainees learn how to handle port equipment according to the best industry practices.

It includes:

- Progressive exercises to build confidence and gain experience

- Pre-operation and start-up procedures

- Broad range of load types

- Different weather and wind operating conditions

It enables the trainee to perform the following true-to-life equipment functions:

- Gantry, trolley and hoisting movement

- Fully articulated Bromma spreader

- GPS and load movement indicator

- Collision detection rods

- Carrying

4. Straddle Carrier

Learning on the Straddle Carrier training simulator enables trainees to operate this essential yard side equipment safely and progressively. Simulation gives them hands-on training time, and prepares them to transition to real equipment in busy working conditions.

The simulator’s exercise programmes include:

- Unloading on flatbed container chassis and in the container yard

- Working with multiple load types, including regular, refrigerated and open-top containers

- Port driving and following traffic rules

- Variable weather and wind conditions

This package applies true-to-life simulation to competency-based training, where trainees will experience working in a demanding port environment.

The simulator replicates the features and actions of real equipment, including:

- Equipment suspension system

- Hoisting and spreader systems

- Acceleration, breaking and turning

It also replicates equipment faults to present trainees with the kinds of issues they might face in an actual working environment.

5. Reach Stacker

Like the other yard side simulator training packages, the Reach Stacker simulator provides true-to-life training in a port environment.

It is a progressive learning package including:

• Pre-operation and start-up procedures • Multiple container types • Varying weather and wind conditions • Realistic fault simulation

The Reach Stacker simulator behaves authentically, replicating the speed, weight and acceleration of real equipment.

It also has these features:

• Boom configuration for containers • Bomb cart and intermodal trailer methods for container delivery and unloading • Automatic and manual spreader modes

All of the simulator’s major components are aligned with manufacturers’ specifications for real equipment.

6. Empty Container Handler

This training simulator provides true-to-life learning based on the mechanics, actions and behaviour of real port machinery.

The Empty Container Handler simulator includes the following features:

- Picking and stacking

- Port driving and following traffic rules

- Adapting to variable wind and weather conditions

- Night time operations

It behaves like real equipment, with lights, sensors, mirrors and sounds.

It will topple if improperly handled, and works with the same load limits as an actual container handler.

These features and actions contribute to an advanced learning experience that prepares trainees for a rapid transition to operating real equipment.

Conclusion

For port terminals to ensure their productivity, they must equip their workforces with the skills they need to compete in an evolving and challenging sector.

Simulation-based training solutions for yard equipment can accelerate the learning process, bringing cost savings and efficiencies for port terminals.

For more information these simulation-based training packages for port operators, please don’t hesitate to contact us.

Download our free eBook on how port equipment training simulators can help to improve the safety and productivity of employees in port terminals.