There is a well-documented skilled labour shortage impacting many sectors in the UK, with the Open University’s Business Barometer recording that over 60% of business leaders reporting that the skills shortage has worsened.

The construction sector in the UK alone generates around €108 billion annually, but it is facing the challenge of a skills shortage, as its retirement rate increases. It is finding it difficult to attract younger recruits with the right skills, or even the willingness to train.

Construction operator training can be costly and time-consuming. The companies operating in the construction sectors that wish to attract fresh talent are finding ways of making operator training more cost effective, rapid, safe and attractive. This also helps the skills shortage in the industry which has limited the construction initiatives while increasing the labour costs.

Advanced construction operator simulation training technology offers advanced, accessible training techniques to construction companies to support their recruitment and talent development.

Heavy equipment operator training simulators reduces training time and capital costs, while ensuring safer training, and better prepared operators in the construction industry.

What are the Costs of Heavy Machinery Operator Training and Assessment?

Training new recruits in any field can end up being a costly process, and in the construction and port industries, there are also direct and indirect costs that come with operator training for heavy equipment.

Direct costs associated with operator training

- The most obvious direct cost is the equipment. To train someone on-site requires heavy lifting and earth moving machinery such as tower cranes, motor graders, backhoes, crawler cranes, dozers, forklifts, and excavators.

- Construction equipment is a costly investment for construction companies if they want to commit to on-site training. The same applies to specialist vocational training schools and institutions.

- These direct costs are reflected in the price of training courses, which can run into several thousands of euros.

- Fuel costs for every hour of use and maintenance of these heavy machines can be quite substantial amount.

- Insurance costs - operators need to be insured against damages to protect both them and your organisation.

- Finally, there are the wages of qualified operators to cover if you employ them as trainers, and the insurance costs that come with physical, on-site training.

Indirect costs associated with heavy machinery operator training and assessment

- Taking the time out for full training of operators can impact on productivity, as it diverts resources away from core operations.

- There is also the risk of workplace injuries, with their associated costs. Frequently, a key factor in construction industry injuries is inexperience. This risk is likely to increase where there is on the job training involved.

- Where there are workplace accidents, costs can escalate, taking in legal costs, compensation, but also reputational damage.

On the job training has, for a long time, been the only type of practical training in the construction industry. However, the development of increasingly accessible simulation training methods now offers a fresh and effective alternative.

How Construction Simulators Help to Reduce Training Costs

Simulation-based construction equipment operator training offers the construction industries opportunities for rapid, efficient and cost-effective training.

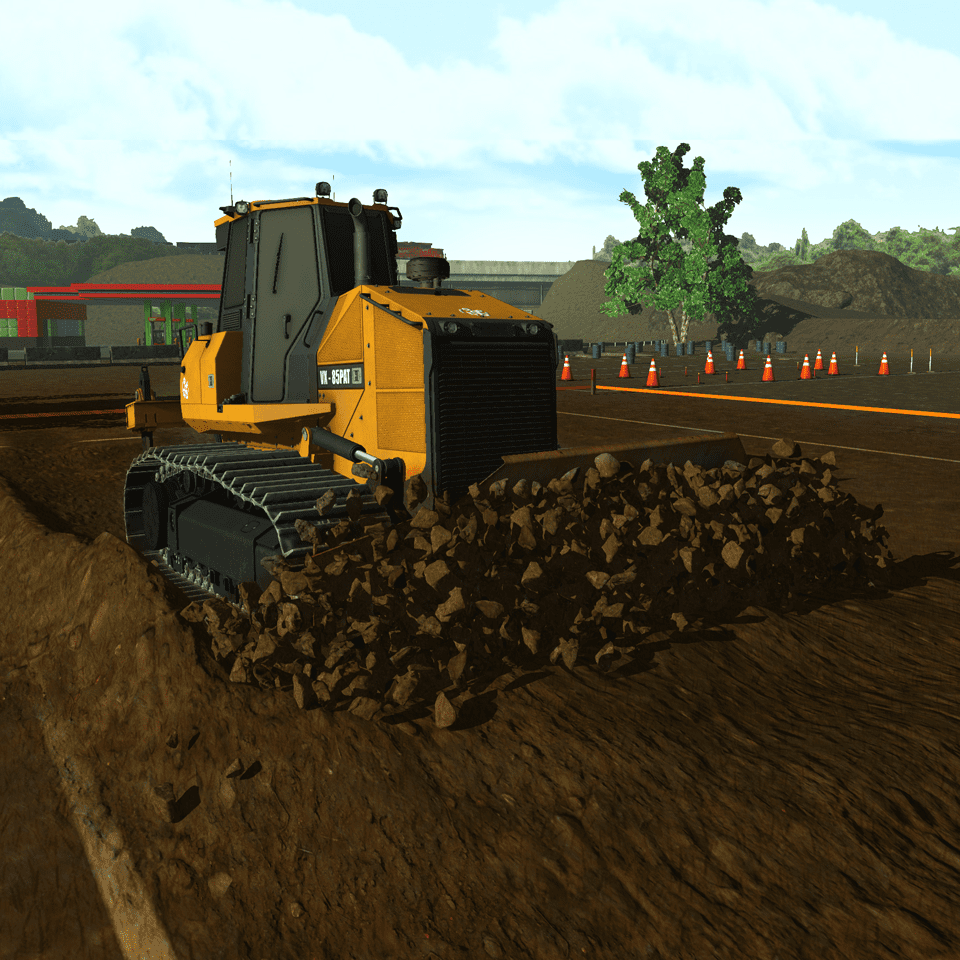

Vortex simulators enable operators to develop real-world skills for operating major heavy machinery such as excavator, dozer, wheel loader, motor grader, mobile crane, tower crane, etc. in an efficient, safe but testing environment.

This form of simulation-based training can reduce training costs significantly for the following reasons:

- Operators can train anywhere at any time, reducing the need and cost of specific, on-site training facilities and equipment.

- Simulation reduces wear and tear on heavy machinery since operators can learn to operate it more effectively before actually using it.

- It reduces downtime for equipment which would otherwise be needed for training purposes.

- It can condense training time, by as much as two-thirds, minimising losses to productivity and maximising staff resources.

- Vortex simulation offers scalable solutions, depending on individual operator training needs, providing flexibility in both costs and resources required.

- Simulation training is safe, boosting learning rates without there being any risk.

In terms of managing resources, construction simulation is fast and adaptable. You can reinforce it with quantitative measurement and reviewing of trainee performance.

Construction companies can separate their training requirements from their core business needs when it comes to equipment, without incurring significant additional expenses.

Modern simulators combine realistic graphics with intuitive user-friendliness. This professional-grade technology is ideally suited to sectors where the increasing complexity of cranes and other heavy machinery requires more demanding levels of training.

What are Vortex Simulators?

Vortex simulators bridge the gap between classroom learning and on the job training, without compromising on the demands they place on individual operator skills development. They include:

- Vortex Advantage – is a state-of-the-art immersive simulator incorporating a full-field view and a dynamic motion platform, with the option of up to five screens to meet the demands of heavy equipment operator training, from cranes to excavators.

- Vortex Edge Max – an accessible, entry level motion simulator, bundled with extensive heavy operator training packages for crane lifting and earth moving equipment.

- Vortex Edge Plus – a portable desktop simulator for training organisations, which can deliver immersive simulation training regardless of classroom location and layout.

What is the ROI of Simulation-Based Construction Equipment Training

Whether it’s training on an articulated crane truck, rough tower crane, earth moving equipment or a forklift, on the job training comes at a cost.

One of the original barriers to wider adoption of simulator training was the cost. Coupled with this was the relative primitivity of early simulators.

Vortex simulators represent the cutting edge in modern simulator technology, offering a cost-effective training alternative that provides the equivalent of the real-world operator experience.

But how does investing in construction simulation training stack up against traditional on the job training in terms of ROI?

Calculating ROI first requires looking at the expenses involved in physical training methods, which includes:

- Machine costs and maintenance

- Cost of fuel per day

- Depreciation costs

- Insurance

- Cost of trainers.

Typically, where a standard training course in construction equipment might last 20 days, with six students enrolled on it, cost totals will include fuel use per hour, maintenance per hour and depreciation costs per day.

Equipment costs can be either for the equipment you own but ring-fence for training, or for renting equipment specifically for training purposes.

Added to this will be trainer costs and insurance. Ultimately, the total cost for this type, of course, could run to over €20,000.

However, with equipment simulation training, this should look a lot different:

- Even with a combined training approach involving simulation and physical equipment, you will reduce machine costs, and the cost of the fuel you use

- You are not using resources you would otherwise deploy elsewhere, so there is no loss of productivity

- Insurance cost come down because your operators are mainly training on simulation devices

- The whole process is more rapid, and therefore efficient, saving on time spent on training and freeing up trained staff sooner, who can then contribute to productivity.

Case Studies of Vortex Simulators in Construction

1. The Construction Industry Training Board (CITB), based in the UK, has announced it will use Vortex Advantage training simulators as part of its crane operator training programme.

The forecast shows that the industry needs to fill 179,000 new jobs in the next five years. That’s why CITB is embracing new technologies to help raise their performance.

Complementing the crane training simulators will be Vortex Signaller Stations, enabling trainees to practice team-based signalling in the same simulation environment.

2. In Canada, a heavy equipment and crane training school has upgraded to Vortex Construction Equipment Simulators and instructor stations for crane operator, heavy equipment, and construction safety training programmes.

By having this readily available equipment, apprentices have been able to spend extra time in simulation training, reducing time spent on real world equipment by a full week in every six week course.

3. A Texas-based labour union has replaced its old training simulator with a newer Vortex simulation technology.

In a single month, the new Vortex simulator is used 120 hours more than the actual cranes in the sites, helping apprentices sharpen their skills with simulation based training.

4. A mid-Atlantic design-build general contractor, has been able to reduce its on-site crane training time from six months to seven weeks, using a Vortex Simulator.

This has led to a reduction in crane training time to 7 weeks and training costs halved.

Why Use Simulation Based Training?

Adopting simulation as a training method could help the construction industries present a more dynamic, modern face to the world, while giving them a much-improved ROI, productivity, reduced costs and equipment usage.

Simulation-based training fulfills key training objectives, including:

- construction equipment training

- construction operator training

- health and safety training

- lifting equipment training

Vortex simulation systems include swappable controls, motion platforms, and are scalable in the number of screens they employ. They allow users to take a self-learning approach and include performance metrics and scoring.

ST Engineering Antycip (formerly Antycip Simulation) has partnered with CM Labs to provide dedicated training simulators and simulation software to Europe’s construction, highways, ports, and training sectors.