VR IN ENGINEERING

Virtual reality (VR) is enhancing how businesses in the architecture, engineering and construction (AEC) industry collaborate with each other, and with their clients. VR has enormous potential as the next evolutionary step forward from Building Information Modelling (BIM), and its realisation is driving a trend towards wider adoption.

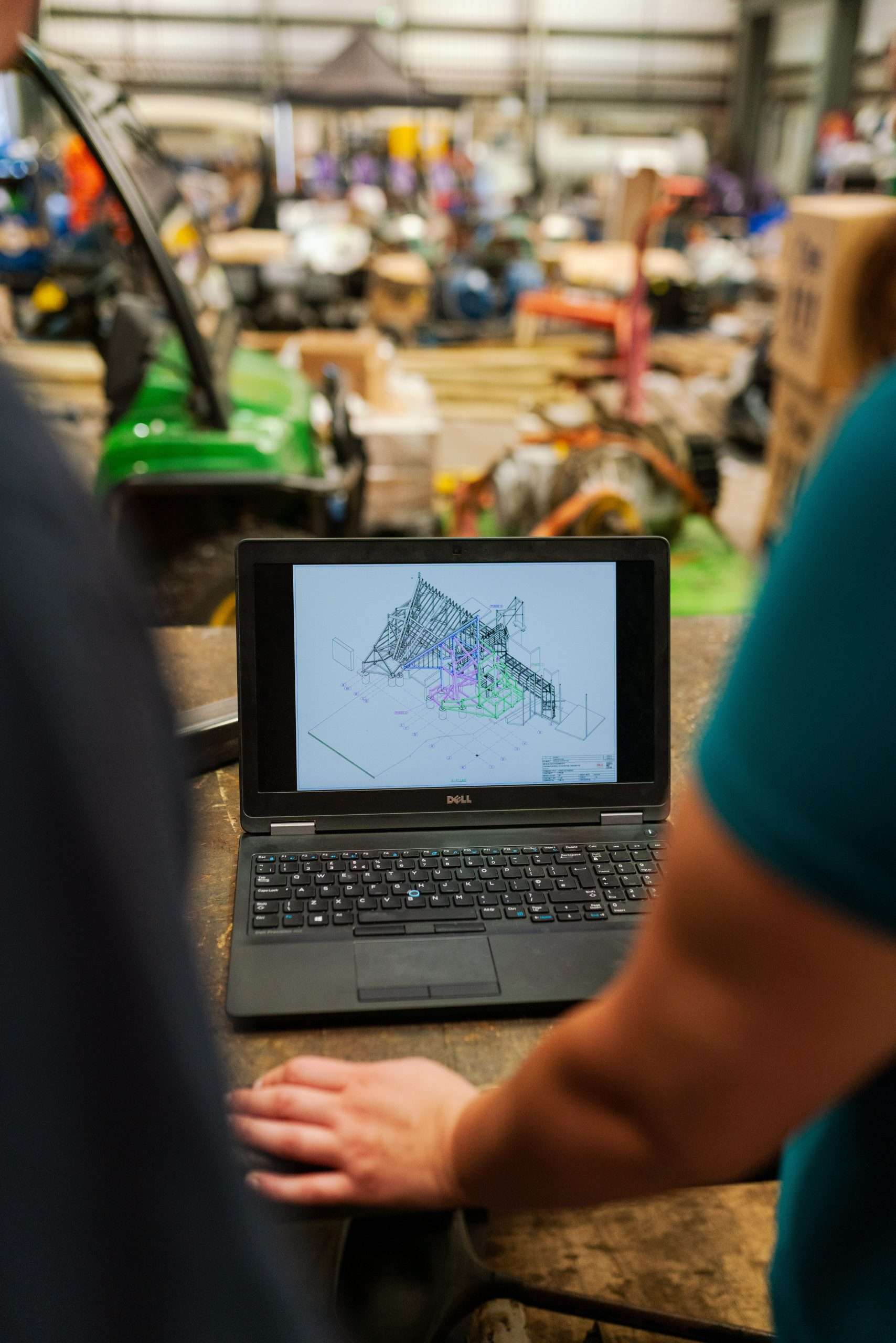

In the engineering sector, VR applications such as 3D modelling are used as an advanced visualisation technique.

ST Engineering Antycip, in partnership with TechViz and Barco, is delivering VR solutions to AEC enterprises across Europe. VR presents plenty of opportunity for future aspects of working together, but its application as a practical tool can add immediate value to the AEC sector.

HOW IS VR SHAPING THE AEC INDUSTRY?

VR is changing how different sectors work within the AEC industry.

In architecture, VR highlights human elements of form, space and aesthetics to engage clients and stakeholders in projects. VR visualisations enable people to walk through immersive scenarios which recreate designs as if they were already built.

VR can also be a group collaborative tool, where professionals in the built environment can share visualisations, and interact with them in real-time. It enables instant feedback and helps pinpoint precise details as well as giving an accurate rendition of what a completed project will look like.

In engineering, as well as in architecture, VR is fast becoming an advanced design tool, which can enhance existing BIM capabilities and open up whole new opportunities for visualisation and collaboration. Manipulating 3D models in a highly realistic virtual setting enables engineers to spot flaws and potential risks early in the design and development process, taking virtual prototyping to a whole new level.

In construction, VR can drive new efficiencies and provide a stronger more effective collaboration between parties, while engaging stakeholders and end-users. It allows for testing and exploring structures before anything happens on-site and has potential for improving cost-effectiveness and risk mitigation.

Another vital element of VR in construction is as a training tool. This applies both to health and safety awareness, and to competency in handling specialist equipment.

WHAT IS THE ROI OF VR IN AEC?

Regardless of VR’s innovative qualities and its potential to transform how engineering and other AEC sectors work, the bottom line remains a key concern. Perceiving VR as very much an innovative and specialist technology, companies can struggle to see how it will provide a demonstrable ROI.

The first thing to consider is the cost versus benefits. According to a study from Capgemini, “three in four companies using VR can attest to operational benefits of over 10%”

What VR offers is a means of saving time and money while developing projects and bringing them to market. Also, virtual reality enhances teamwork and collaboration because it overcomes the team’s challenges and makes understanding easier. It also enables companies to improve the quality of products, and to test their impact on stakeholders and end-users much earlier in their production lifecycle.

For example, in a non-VR process, there may be various design errors which slow down prototyping and are costly in terms of overall delays to project milestones, schedules and deadlines. VR can cut down on the amount of design errors, thereby speeding up the entire process and saving money in production time and manpower. VR technology does represent an investment, going beyond headsets to include items such as immersive, large-scale displays.

According to an NVIDIA report, “projects that fully integrate VR technologies are seeing a 60-65% reduction in the number of design issues”. When used correctly, the ROI of VR can be quickly calculated within few months after its integration.

An example of a decreased time to market is jet manufacturer Embraer’s design of its Embraer E170 aircraft, which took only 38 months to complete, nearly half the time of its previous project (ERJ145) which took 60 months.

Another example is where Ford used VR technology to identify, and then engineer alternative actions following studies capturing data from operators equipped with full body motion sensors during assembly tasks. This resulted in a 70% drop in employee injuries and a 90% reduction in ergonomic related issues.

WHAT OTHER TECHNOLOGIES AND DEVICES COMBINE WELL WITH VR?

Various technologies, and different devices, can interact and integrate with VR to enhance its capabilities for engineering and other AEC sectors. These include:

- Artificial intelligence (AI)

- Robotics

- 3D point cloud data

- Tracking devices

- Digital Twins

Both AI and robotics benefit from VR input, for testing environments and simulating scenarios. Using 3D point clouds, you can map existing structures or environments to combine them with VR.

Digital twin technology allows access to data from real-world assets, but using virtual simulation. This means you can supplement actual data with predictive VR-generated information.

CONCLUSION

VR is an enabling technology that promotes better explanation and understanding of projects, and supports cost-effective research, development prototyping and training. As more AEC enterprises discover the potential benefits of virtual reality, it is set to become an integral part of the digital transformation programme.

ST Engineering Antycip and our partners TechViz & Barco can help your organisation in the development of your VR collaboration projects which enables you to display 3D datasets in a VR system (such as VR headsets, powerwalls, immersive rooms) directly from any CAD without the traditional and time consuming workflows of old.

For more information about ST Engineering Antycip’s innovative VR solutions for architecture, engineering and construction sector, please contact us regarding your VR collaboration project.