Electric vehicles are the future of transport.

Not only does a global effort to move away from fossil fuels spur the pursuit of cleaner, greener forms of travel, but big pushes from the governments of many nations are also ensuring that vehicle manufacturers must focus on EVs sooner rather than later.

New buildings in the UK will soon be required to have electric charge points installed by law.

France was the first EU country to pass legislation to phase out petrol and diesel cars, providing that the sale of new passenger cars and light commercial vehicles using fossil fuels must end by 2040.

With the use of EVs set to become so prevalent in the near future, their development is essential to ensure successful widespread integration.

Simulation can — and, to some degree, already does — play a key role in this.

Why use driving simulators for vehicle development?

Driving simulators are effective for training drivers without putting them in the seat of a real car, on a track large enough to practice on, and in favourable weather.

And when it comes to vehicle development, they have as much to offer.

Engineers and product designers can monitor the performance of a vehicle’s digital twin in the simulator, and apply the knowledge gained to the real-world vehicle in development.

Drivers can ‘test drive’ the car and give their feedback to avoid wasting both money and time.

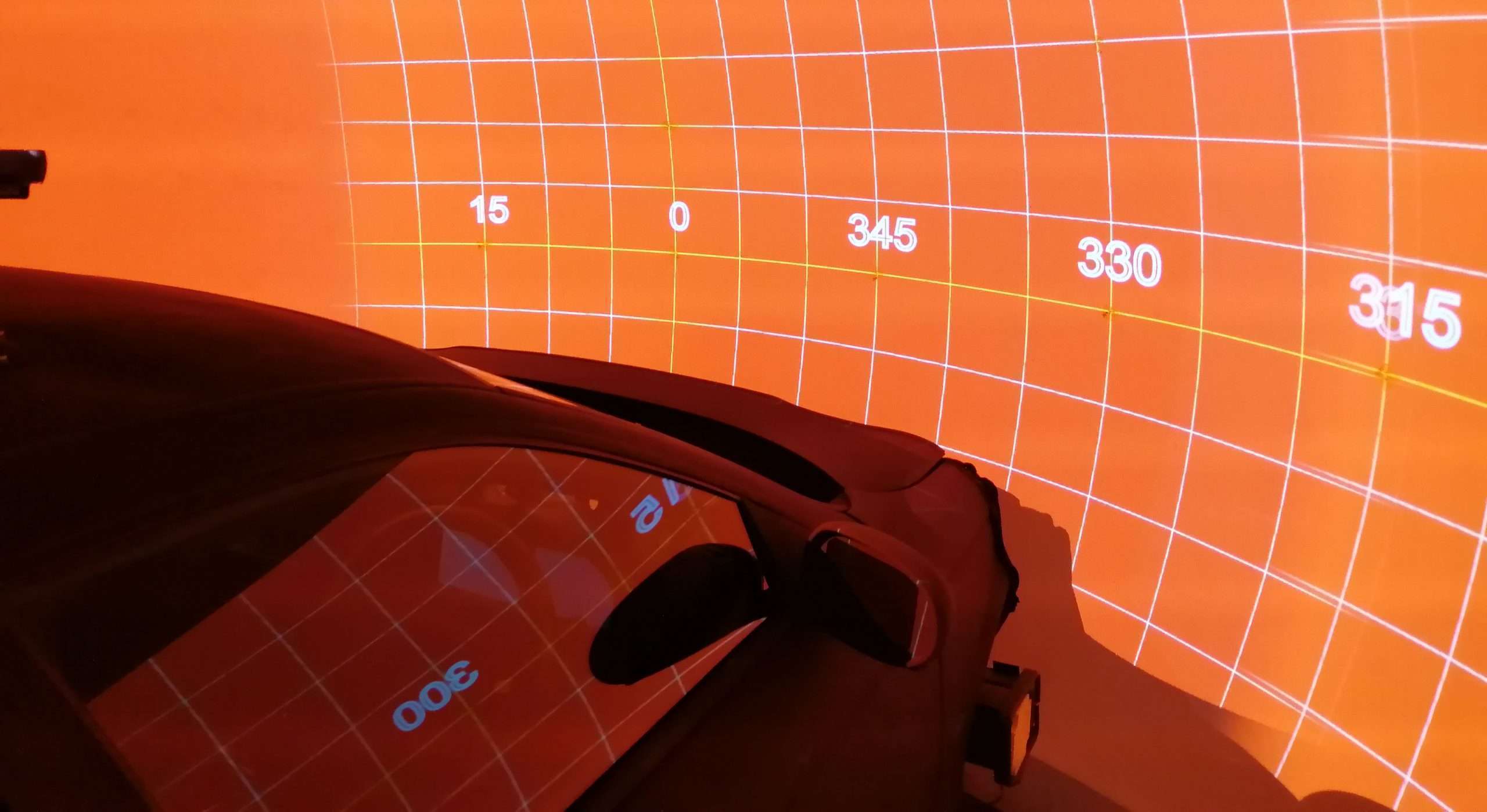

When constructed with the right technology and expertise behind it, driving simulation is incredibly immersive.

ST Engineering Antycip has even provided solutions for simulators using real car components and interfaces.

Given a simulator can simply be restarted and rerun as many times as necessary with the required variations and tweaks, a car can be fine tuned and tested again and again with an intensity that would be far too demanding for real-world track testing.

Using accurate data, the results of simulator testing can be just as valid and true.

What challenges do EVs face?

EVs come with their own set of challenges despite the advantages of their cleaner fuel source and operation.

One of the largest challenges and concerns for future EV buyers is that of range.

Currently, an electric vehicle simply cannot travel as far on a full charge as a liquid fuel-based car with a full tank of petrol or diesel.

Development into more efficient lithium-ion batteries is ongoing, but in order for widespread EV usage to become a reality, batteries must charge faster and hold more power.

There are additional challenges regarding EV battery usage, such as thermal management. Managing the temperature of EV batteries can be tricky, as periods of high usage, charging, and high ambient temperatures can affect the heat levels of the battery itself.

Despite the challenge of managing battery heat, it’s nevertheless vital to do so as a specific temperature range is needed to get optimal performance. The same goes for the electric drive and any other systems that generate, and are affected by, heat.

Another challenge faced by EVs is longevity. Many car buyers opt for second-hand vehicles as opposed to new, and while this isn’t typically a problem for liquid fuel-based vehicles, the lifespan of EV batteries and electrical components for the years after their manufacture remains to be seen in the context of a secondhand market.

In the UK alone, there were over 7.5m used car sales in 2021, highlighting the significance of the secondhand vehicle market which EVs must inherit.

Not to mention the issue of charging

How can driving simulators help with EV development?

Many of the challenges faced by EV development lies in ensuring that EVs can provide as much travel range per charge as possible while having lifespans that don’t make them dramatic downgrades from traditional petrol and diesel vehicles.

Driving simulators can help not only understand the current limits of EV range and longevity, but they can provide the ideal platforms to test redesigns and upgrades without needing to prototype and then test them on a physical track.

Simulators are as measurable as ‘the real thing’ for the purposes of testing without demanding the same levels of cash (and time) investment.

For an example of this, look no further than Ford’s 2019 making of the Mustang Mach-E, an electric SUV that could be ‘test driven’ using a simulator. When a company director expressed disappointment with the vehicle, there was no costly prototype rendered worthless — they simply had to change the simulation.

Driving simulators have a strong future in the automotive industry, especially as the world pushes for an all-electric transport paradigm.

To learn more about how simulation is the future of training, testing, and R&D, contact ST Engineering Antycip today.